Chapter 1: HDPE History and Background

High-density polyethylene (HDPE) popularity and usage continues to increase. Plastic, particularly HDPE, is part of our everyday lives, from household products to industrial applications. Since its creation almost 70 years ago, HDPE piping and conduit has become a preferred material in the power, communications, and energy industries. HDPE conduit is a flexible and versatile product well-suited for numerous industrial settings. Specific applications include conduit for telecommunications and fiberoptic lines; flowlines for oil and gas; gas transmission and cross-country pipelines; and municipal water and sewer lines.

Image Courtesy of National Inventors Hall of Fame https://www.invent.org/

HDPE was discovered by scientists at Phillips Petroleum in 1951. Polyethylene, a low-density thermoplastic with a variable crystalline structure, was invented in the 1930s by Imperial Chemical Industries. High pressures – 20,000 to 30,000 pounds per square inch (psi) – are required to produce polyethylene. Phillips scientists J. Paul Hogan and Robert Banks developed a process using nickel oxide and chromium oxide catalysts that produced a new ethylene polymer at much lower pressures than required for traditional polyethylene. The new material, HDPE, was harder, stronger, more durable and more heat-resistant than any existing plastic material. The methods they developed are still used to produce HDPE today.

The scientists who discovered HDPE patented the process and Phillips began marketing the material under the brand name Marlex in 1954. After a slow start, Marlex became wildly popular thanks to an unlikely source of demand: the hula hoop. Hula hoops are essentially plastic tubing on a much smaller scale than the industrial applications that use HDPE today. As demand for hula hoops grew, Phillips improved the HDPE production process and offered the material in different grades. Marlex soon found additional applications in baby bottles and household products. Today, HDPE has become one of the most popular plastic materials for both industrial and consumer applications, thanks to its durability and strength.

The scientists who discovered HDPE patented the process and Phillips began marketing the material under the brand name Marlex in 1954. After a slow start, Marlex became wildly popular thanks to an unlikely source of demand: the hula hoop. Hula hoops are essentially plastic tubing on a much smaller scale than the industrial applications that use HDPE today. As demand for hula hoops grew, Phillips improved the HDPE production process and offered the material in different grades. Marlex soon found additional applications in baby bottles and household products. Today, HDPE has become one of the most popular plastic materials for both industrial and consumer applications, thanks to its durability and strength.

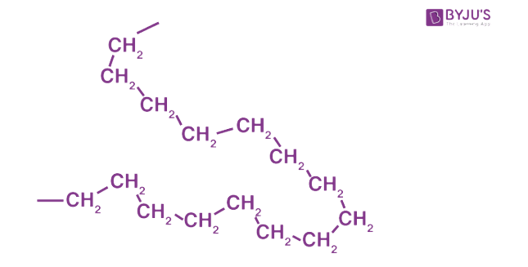

HDPE Definition

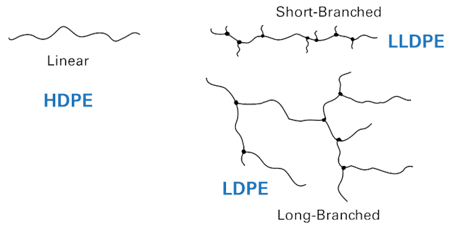

HDPE is a high-density plastic that is strong yet flexible. HDPE has a linear molecular structure, unlike low-density polyethylene (LDPE), which has a branched molecular structure. The linear molecular structure of HDPE allows its polymer chains to pack closely together, creating a dense and strong material. While LDPE is cheaper to produce and more flexible, HDPE’s strength and durability make it an ideal product for many industrial and household applications. HDPE materials like pipe are manufactured from resin.

HDPE is much stronger and lighter in weight than conventional pipe, yet more flexible than materials like concrete and iron. HDPE heat-fused joints are as strong as or stronger than metal pipe and do not leak. HDPE pipe offers unmatched corrosion and chemical resistance as it will not corrode (rust), tuberculate or support biological growth. HDPE pipe is expected to have a service life of 50 to 100 years and is fully recyclable.

Download a PDF of the HDPE Guide

Want your own copy of the guide to all things HDPE? Download it for free.

Want your own copy of the guide to all things HDPE? Download it for free.

HDPE and Plastics Organizations

Three organizations have had significant influence on the adoption and usage of HDPE piping: The Plastics Pipe Institute (PPI), the American Society for Testing and Materials (ASTM) and the American Water Works Association (AWWA).

Founded in 1950, PPI is the major trade association representing all segments of the plastics piping industry. The PPI mission is to advance the acceptance and use of plastic pipe systems through research, education, technical expertise and advocacy. The PPI’s publications index page contains comprehensive reports related to specific areas of design, operation and manufacturing. It is intended to assist engineers, code officials, specifying groups and users with information on implementation of plastic pipe.

ASTM, organized in 1898, is a nonprofit standards-developing organization covering global industries in 140 participating countries. Volunteer members serving on standards-writing committees develop technical documents for numerous industry sectors including plastics. ASTM’s plastics committee has over 500 members. The standards developed by the ASTM are intended to ensure quality and safe use of plastic material, including pipe.

AWWA is an international nonprofit scientific and educational society founded in 1881. It is dedicated to providing total water solutions that ensure effective water management. AWWA provides HDPE-related manuals and standards that assist engineers with design, specification, procurement and installation procedures of HDPE pipe and fittings.

Chapter 2: Benefits of HDPE

The modern world cannot function without pipe. Pipes house electrical and telecommunications wires, transmit gas through state and cross-country pipeline systems, and carry drinking water. Most people don’t think about pipes until they break, causing a gas leak, flood, or power outage. Technology has improved over the past century, and many older pipe materials, like lead, clay and cast-iron, have been replaced with highly durable modern materials..png?width=600&height=208&name=BenefitsofHDEP(2).png)

Why HDPE?

Plastics are now the preferred material for telecommunications, energy, and power applications. The high-density plastic HDPE is ideal for these applications, as it is lightweight, corrosion-proof and resistant to bacteriological and chemical buildup.

HDPE operates at a wide range of temperatures and does not become brittle in cold temperatures. It is both strong and flexible, with a failure rate of only 1 in 10,000,000 incidents. It is ideal for underground installation in locations where soil shifting (compaction/expansion) or earthquakes are known to create openings in joints. HDPE’s high ductility and ability to resist deflections from ground movement can withstand the shock, pressure and movement that can potentially destroy rigid pipe.

HDPE Compared to Other Materials

Compared to the other materials on the market, HDPE conduit is preferred for industrial applications like electrical, oil and gas, and telecommunications. Alternative materials for industrial piping include PVC, iron, copper and concrete.

PVC Pipe

Common uses for PVC pipe include electrical and telecommunications systems. While both materials are plastics, PVC is stronger and stiffer than HDPE. However, PVC has a higher failure rate than HDPE and does not perform as well in extreme weather or temperature conditions. Leakage can also be a problem in mechanically joined PVC pipes.

Common uses for PVC pipe include electrical and telecommunications systems. While both materials are plastics, PVC is stronger and stiffer than HDPE. However, PVC has a higher failure rate than HDPE and does not perform as well in extreme weather or temperature conditions. Leakage can also be a problem in mechanically joined PVC pipes.

Iron Pipe

Primarily used for gas, water and sewage applications, iron pipe is strong, withstands high internal and surge pressures and has a long service life. Disadvantages include limited flexibility, high transportation cost (joint lengths and weight) and susceptibility to corrosion.

Primarily used for gas, water and sewage applications, iron pipe is strong, withstands high internal and surge pressures and has a long service life. Disadvantages include limited flexibility, high transportation cost (joint lengths and weight) and susceptibility to corrosion.

Copper Pipe

Pipes made of copper have a higher resistance to corrosion and are more flexible than iron pipe. However, copper pipe is more expensive and less flexible than plastic pipe like HDPE. Copper piping is prone to failure when exposed to extremely high and low temperatures.

Pipes made of copper have a higher resistance to corrosion and are more flexible than iron pipe. However, copper pipe is more expensive and less flexible than plastic pipe like HDPE. Copper piping is prone to failure when exposed to extremely high and low temperatures.

Concrete Pipe

Used primarily in sewage and drainage applications, concrete pipe is rigid and does not corrode. However, concrete pipe is heavy and is not suitable for other applications where HDPE is used. Its weight and rigidity make it less than ideal when shipping, handling and installing.

Used primarily in sewage and drainage applications, concrete pipe is rigid and does not corrode. However, concrete pipe is heavy and is not suitable for other applications where HDPE is used. Its weight and rigidity make it less than ideal when shipping, handling and installing.

HDPE Installation

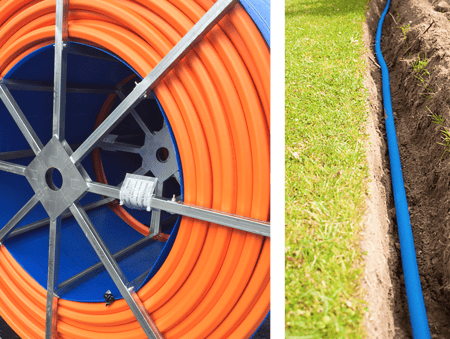

In many situations, installing HDPE pipe is cheaper and easier than installation of other materials. HDPE weighs much less than concrete, iron and steel pipe, so transportation costs are lower and no heavy lifting machinery is required. HDPE is typically delivered in long-length coils, spools or sticks of straight pipe. Supplying HDPE on spools or coils can also reduce transportation costs as fewer deliveries are necessary.

In many situations, installing HDPE pipe is cheaper and easier than installation of other materials. HDPE weighs much less than concrete, iron and steel pipe, so transportation costs are lower and no heavy lifting machinery is required. HDPE is typically delivered in long-length coils, spools or sticks of straight pipe. Supplying HDPE on spools or coils can also reduce transportation costs as fewer deliveries are necessary.

HDPE installation requires fewer joints and fittings than other piping solutions, saving time and money during the installation process. Because HDPE is so flexible, it can be bent without requiring additional joints or fittings. This flexibility allows HDPE to be installed without trenches and over uneven terrain. Joints are typically heat-fused, and are as strong as the original pipe and do not leak. HDPE is also durable, with an expected service life of 50 to 100 years, and is fully recyclable.

HDPE can be installed using standard methods like pipe bursting, horizontal directional drilling, trenching and microtrenching. Each installation method is fully described in chapter 5.

Chapter 3: HDPE Manufacturing Process

HDPE pipe is manufactured from resin, which is made from natural gas feedstock. Resin arrives to the manufacturer via rail and is stored in tanks onsite until the manufacturing process begins. Atkore - United Poly Systems follows the industry standard manufacturing process and performs additional QC and testing throughout.

Receive and Test Raw Material

The first step in the manufacturing process is receiving the raw material: HDPE resin. Resin is shipped by rail in the form of small, colorless pellets and is inspected upon receipt. The resin manufacturer provides material certification, production codes and data for each batch of resin. All of this information is stored and provided to customers to ensure full traceability of all material. If there is ever a question about material origin or quality, or if there is a material failure in the field, pipe manufacturers have a complete record of the incoming material, and can identify how much pipe was made with the specific batch of material.

Resin is typically stored onsite in silos for easy distribution to the production lines. Before the manufacturing process can begin, the resin must be carbon black tested. Carbon black testing is an ash test that measures the carbon content of the HDPE resin. Carbon black is a UV stabilizer that prevents HDPE pipes from degrading when exposed to sunlight and each type of pipe requires a specific carbon black content. For example, high-pressure pipes require 2% carbon black content for UV protection. Carbon black is derived from the color additive and is added to the resin mix before extrusion.

Batching, Heating, Blending and Extrusion

The first step of manufacturing is batching. This involves drawing the resin through pneumatic tubes to the production line. At this point, color additives and/or striping are introduced.

Next, the resin is added to a heating element and blended with a tapered screw. After the resin heats and mixes, it is pulled out through a die head. The desired pipe dimensions are input to the system and the resin mix is added to the extruder. The amount of material allowed into the extruder is closely monitored; the system automatically controls the material allowed to flow into the extruder, based on how much material should be in each foot of pipe.

Sizing and Cooling

After the material leaves the die head, it enters a vacuum tank where it is held at the correct diameter. It is sprayed with water, causing the material to cool and harden, setting the dimensions. The cooling process involves several rounds of exposure to water tanks and open areas to ensure that the pipe dimensions set correctly.

After the material leaves the die head, it enters a vacuum tank where it is held at the correct diameter. It is sprayed with water, causing the material to cool and harden, setting the dimensions. The cooling process involves several rounds of exposure to water tanks and open areas to ensure that the pipe dimensions set correctly.

Quality Control

Pipe is inspected for quality at all steps in the manufacturing process. Throughout extrusion, the operator centers the pipe to ensure the wall thickness is uniform and confirms that every dimensional aspect is accurate. Samples of extruded pipe are taken before and during each production run to confirm specifications such as tensile strength, burst rating and dimensions.

Pipe is inspected for quality at all steps in the manufacturing process. Throughout extrusion, the operator centers the pipe to ensure the wall thickness is uniform and confirms that every dimensional aspect is accurate. Samples of extruded pipe are taken before and during each production run to confirm specifications such as tensile strength, burst rating and dimensions.

Printing

As the finished pipe exits the extrusion machine, additional striping can be added to the pipe for further identification. A print line is hot-indent stamped into the surface at the end of the manufacturing process. Information like date, location, material code, footage and manufacturer name is also stamped onto the HDPE pipe at this stage.

Cutting, Packaging and Shipping

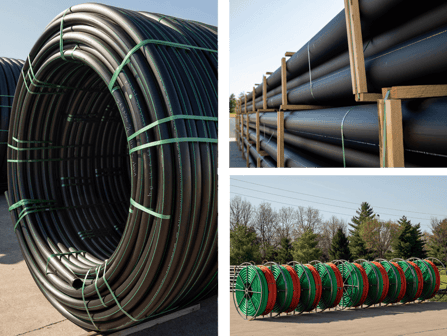

Once a length of pipe is complete, it is cut with a rotary automated cutter. The rotatory cutters radiate at high speed and slowly cut into the wall of the pipe, so the cut is smooth and uniform. The extruded, inspected and cut pipe is then prepared for shipping on either coils, reels or straight-line sticks.

Once a length of pipe is complete, it is cut with a rotary automated cutter. The rotatory cutters radiate at high speed and slowly cut into the wall of the pipe, so the cut is smooth and uniform. The extruded, inspected and cut pipe is then prepared for shipping on either coils, reels or straight-line sticks.

-

Coils: Coiling machines wrap the extruded pipe. The coilers have paddles on the end that can hold the pipe to itself, forcing it to wind onto a coil without an inner core of any kind. Once the coil is complete, it is banded, removed from the machine, and placed upright for shipment.

- Reels: The reel process is similar to the coil process, except a large metal reel is slid onto the coiler and physically attached to the pipe. The pipe wraps around the reel. When complete, the reel is banded, removed from the coiler and set aside for shipment.

- Straight line or sticks: Straight pieces of pipe are cut to length, positioned on pallets, and banded for shipment.

Once the pipe is packaged, it is ready to ship. HDPE pipe is typically shipped via flatbed or box trucks.

Standards

All pipe from Atkore - United Poly Systems is manufactured to meet or exceed standards and specifications.

- Comm-Line meets or exceeds ASTM F2160 standard

- Hard-Line and Stream-Line meet or exceed ASTM D 3350 standard

- PA-12 meets or exceeds ASTM D1598 standard

- MDPE meets or exceeds ASTM D2513 and ASTM D3350 standards

- Power-Line meets or exceeds ASTM F2160 and ASTM D3350 standard

- Power-Line and Sleeve-It! meets or exceeds ASTM F2160 and ASTM D3350 standards

- Sleeve-It! meets or exceeds ASTM F2160 standards

| Suite | Product | ASTM F2160 | ASTM F2619 | ASTM D1598 | ASTM D2513 | ASTM D3350 |

|---|---|---|---|---|---|---|

| Stream-Line | MDPE | X | X | |||

| PA-12 | X | |||||

| HDPE gas pipe | X | X | ||||

| O&G pipe | X | X | ||||

| Conduit | Comm-Line | X | ||||

| Power-Line | X | X | ||||

| Sleeve-It! | X | |||||

| Hard-Line | X |

Chapter 4: HDPE Applications

HDPE pipe is the ideal material for a variety of industrial, energy, and telecommunications applications. It’s both durable and flexible, long-lasting, and easy to install. Maintenance and transportation costs are low, and the pipe can be customized for specific uses. HDPE pipe is used in both pressure (transporting fluid at high pressure) and conduit (encasing wires and cables) settings.

Pressure Applications

HDPE pipe is resistant to fatigue and handles high flow velocities. Pressure applications include oil and gas, mining, and others.

Energy and Industrial

Industrial operations like oil and gas and mining are often in rough environments. HDPE performs well in rugged environments and harsh climates. It is durable and will not crack or break in extreme weather conditions. Installation is easy, which is ideal for expensive operations, and the pipe can easily be pulled and moved from one location to another. Additionally, HDPE is resistant to abrasion and corrosion, which is critical when transporting chemicals, gases, and waste materials.

HDPE pipe is used for the following oil and gas and mining applications:

Oil and Gas: transmitting oil and gas from the wellhead to storage tanks or sales lines and in cross-country pipelines; regulated gas transmission; transmitting produced and treatment water at oil and gas well locations.

Mining: Transporting and collecting process water, chemicals, waste, leachate and mineral slurry; dewatering pits; heap leaching.

Conduit

HDPE pipe is used as conduit to encase electrical and telecommunication lines. It is ideal for housing power lines and cables underground, as it can withstand earthquakes and extreme temperatures and is corrosion-resistant. HDPE comes in long lengths and can be installed horizontally, which is advantageous for upgrading existing infrastructure. Conduit applications include power and telecommunications, and microduct.

Power and Telecommunications

HDPE pipes are durable and will not be affected by harsh soils or seismic events when underground. This makes HDPE the ideal material for housing critical electric and communications lines underground.

HDPE pipe is used for the following power and telecommunications applications:

- Encasing electrical power lines in municipal utilities, highway lighting, site lighting, signal and control, intelligent transportation systems (ITS), and supervisory control and data acquisition (SCADA)

- Encasing fiber optic cables, network cables and telephone lines

Microduct

Microduct HDPE pipe is a new alternative to traditional cabling. These products are typically branded by their manufacturers. For example, Atkore - United Poly’s proprietary microduct product is called MicroPath. This type of pipe has multiple built-in micro ducts for fiber cabling. It is ideal in constricted areas where there is little room to expand or install new casing. Microduct is increasingly used to replace or upgrade existing infrastructure. Broadband infrastructure upgrades related to the Broadband Pilot ReConnect program and the CARES Act are ideal applications of HDPE conduit.

Microduct HDPE pipe is used for housing fiber optic cables in the telecommunications and utilities industries.

HDPE’s durability and versatility make it an excellent material for a variety of pressure and conduit applications: industrial, residential, telecommunications, energy and more.

Chapter 5: HDPE Pipe Installation Methods

There are almost as many installation methods for HDPE pipe as there are applications, sizes and colors. This article describes some of the most common methods. Detailed descriptions of each can be found in the Plastics Pipe Institute (PPI) Second Edition Handbook of PE Pipe 2008.

Pipe Bursting

Pipe bursting with HDPE pipe has become a practical solution for replacing/rehabilitating the nation’s aging infrastructure. Pipe bursting is a trenchless method to replace buried sewer and water piping without the need for a traditional construction trench and associated equipment.

In this process, HDPE pipe is pulled through existing pipe, essentially ‘bursting’ the older pipe with new high-density polyethylene. This technique can be used to replace several types of older pipe including asbestos cement (AC) pipe, vitrified clay pipe (VCP), ductile iron, cast iron, plain concrete, plastic and reinforced concrete pipe (RCP). This less-invasive method leaves the remnants of the old pipe in place; no digging, haul-off or disposal is needed. This method can also be more cost effective. For example, other methods of removing AC pipe are three to five times more expensive than pipe bursting. The pipe bursting method is in full compliance with all federal regulations and guidelines.

Horizontal Directional Drilling (HDD)

Horizontal Directional Drilling (HDD) is often used to install HDPE pipe in situations where an obstacle, either above ground or below the surface, does not allow traditional installation methods to be used. In this method, a small borehole is drilled under the obstacle that must be crossed, such as a highway or river. Another larger bit, or reamer, is run through the hole a second time, increasing the hole size. Several reamer runs of progressively larger sizes may be necessary to reach the desired hole size. Finally, the pipe is pulled through the hole and connected to the line. The fusion joints and standard lengths of 40 or 50 feet reduce the number of overall joints in the pipe and allow for tougher handling of material with less concern for damage compared to other materials.

Micro-Trenching

For installing smaller conduit lines such as Internet, electrical and microduct products, micro-trenching presents the best option. In this method, a small vertical trench or slot is cut next to the highway, street or sidewalk and the line placed and covered. This can be performed quickly, without impeding busy traffic areas, and does not require heavy equipment or excavation.

Benefits of micro-trenching include minimal traffic disruption, time and material savings.

Plow

In this method, a long, narrow trench called a furrow is created by a plow blade pulled by a tractor or mounted to a railroad car. The furrow is cut in the earth and conduit is placed through the plow’s chute. As opposed to trenching, the plow method does not actually remove soil from the trench. It only displaces the soil as the plow is dragged through the ground while the conduit is installed.

Direct Burial

HDPE pipe can be installed via direct burial safely at depths from 2 to 25 feet where no traffic is present and from 3 to 25 feet where a live load is present. With this method, a trench is dug, the pipe is laid in the trench and the trench is filled back in. However, there are many parameters to consider with direct burial including foundation preparation, bedding and fill material, length and depth of trench, pipe diameter and testing.

Slip Lining

Slip Lining will help implement many of the infrastructure upgrades needed across the county. In this method, new HDPE pipe sticks are inserted at strategic access points in the older, deteriorated line. The HDPE sticks are joined into a new continuous line throughout the existing pipe structure. This technique can be used to rehabilitate gas mains, highway and drainage culverts, and other piping structures with extremely satisfactory results. Slip lining has been used to restore pipe as small as one inch, and there are no apparent maximum pipe diameters limits.

Installation Considerations for Microduct

Microduct products may be installed in direct burial applications via micro-trenching or in microduct pathways via air blowing techniques or traditional manual cable pulling/pushing. For outdoor applications, Microduct products are easily and quickly installed in direct buried applications using minimally invasive micro-trenching equipment.

Microduct products may be installed in direct burial applications via micro-trenching or in microduct pathways via air blowing techniques or traditional manual cable pulling/pushing. For outdoor applications, Microduct products are easily and quickly installed in direct buried applications using minimally invasive micro-trenching equipment.

Air blowing methods (ABC) installations are performed by an air blowing technique that reduces the risk of damage to the fiber cable, accelerates installation time and increases the installation distance.

For indoor applications such as optical fiber subscriber drop cable, aerial installation is a proven option. In this method the cable is suspended from the ceiling in the building raceway. This option allows for future upgrades with minimal disruption.

Atkore - United Poly Systems manufactures HDPE pipe for the oil and gas, mining, and power and communications industries. No matter which installation method you’re using, we have the pipe you need. We can advise on installation best practices and support your team throughout the entire process.

Chapter 6: Why Atkore - United Poly Systems

Customer service and quality products are the priority at Atkore - United Poly Systems. Our success can be attributed to our vast experience, extensive client relationships, industry certifications and state-of-the-art manufacturing and quality control processes. Our agile business model allows us to quickly meet customers’ needs without the overhead expenses that are incurred by many of the larger HDPE pipe producers.

Extensive product lines

We offer HDPE piping for pressure (transporting fluid at high pressure) and conduit (encasing wires and cables) uses in ¾- to 26-inch diameters. Our pressure piping applications include oil and gas and mining. Atkore - United Poly Systems’ conduit piping applications include power and telecommunications, and utilities.

We offer fully customizable HDPE conduit options and our off-the-shelf piping is available in a variety of sizes, colors, dimensions and lengths, with or without stripes. Our piping can be customized with a ribbed interior, pull tape, or a lubricated interior for easier installation.

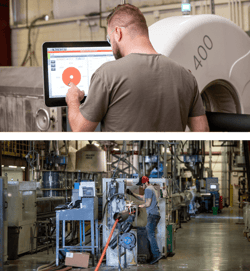

Manufacturing and Quality Control

Atkore - United Poly Systems follows a rigid, multi-step manufacturing process to ensure our HDPE products meet our quality standards. The process begins with receiving the raw material for certification to Atkore - United Poly Systems and industry requirements. We store production codes and data for each batch of material so we can reference any production item after the fact with a simple print line code from the field. The certification is included in the shipping paperwork, and a copy of all documentation is sent to the customer. If there is ever a question about material origin or quality, or if there is a material failure in the field, we maintain a complete record of the incoming material and can verify how much pipe was made from a specific batch of material.

Atkore - United Poly Systems follows a rigid, multi-step manufacturing process to ensure our HDPE products meet our quality standards. The process begins with receiving the raw material for certification to Atkore - United Poly Systems and industry requirements. We store production codes and data for each batch of material so we can reference any production item after the fact with a simple print line code from the field. The certification is included in the shipping paperwork, and a copy of all documentation is sent to the customer. If there is ever a question about material origin or quality, or if there is a material failure in the field, we maintain a complete record of the incoming material and can verify how much pipe was made from a specific batch of material.

Atkore - United Poly Systems performs a thorough quality control check on all samples of extruded pipe. Samples are taken before each production run or every hour, whichever is more frequent. The sample sections are sent to our in-house quality control lab to confirm specs such as tensile strength, burst rating and dimensions. Before the material is loaded and shipped, the order is checked to ensure there are no imperfections and that the entire order was fulfilled correctly.

Packaging, Shipping and Logistics

Atkore - United Poly Systems can ship finished pipe in three different methods: coils, reels or straight line, knows as ‘sticks.’ The shipping option depends on application, installation method and pipe sizing.

HDPE pipe six inches or smaller in diameter is best suited for packaging on coils and reels because of the allowable bending radius. We use 48-inch-wide reels. To minimize ovality in general, we use graduated reel/coil drums. Straight line pipe is generally packaged in diameters of three inches or greater. Since it is packaged horizontally, straight line pipe is at far less risk of buckling and ovaling.

Trucking is the primary transportation option for HDPE pipe. There are three types of truck delivery: flatbed delivery, LTL (less than truckload) deliveries, or a hotshot delivery with a single carrier for fast delivery.

Customer Service

Atkore - United Poly Systems has relationships with top material carriers that deliver on time, take care of the load, and provide exceptional service when unloading the product. We take customer satisfaction very seriously. If a customer has a negative shipping experience, we no longer use that specific truck driver. In the event of a second negative review, we place a hold on business with that carrier.

Our logistics managers maintain open lines of communications between shipping and receiving and the customer. Atkore - United Poly Systems customers can reach out directly to the logistics managers at either manufacturing facility to check their order status. In addition, our drivers will also contact customers to advise that shipments are in transit to ensure deliverability.

Distribution Network

Atkore - United Poly Systems manufactures HDPE pipe from facilities in Springfield, MO and Albuquerque, NM, supporting customers across the United States. Orders can be shipped directly from our manufacturing centers and delivered to multiple project locations to expedite work.

From the east coast to the west coast, Atkore - United Poly Systems has representatives throughout the United States to fully service current and future customer needs. Many of these sales representatives and the distributors they work for have been with UPS since the company’s inception.

Compliant with the Buy American Act

Atkore - United Poly Systems is compliant with Section 1605(a) of the American Recovery and Reinvestment Act (ARRA), which states that goods must be manufactured in the United States. Though components used to manufacture ARRA goods have no country-of-origin requirement to meet compliance, we purchase raw materials in the United States for all finished goods.

Download a PDF of the HDPE Guide

Want your own copy of the guide to all things HDPE? Download it for free.

Want your own copy of the guide to all things HDPE? Download it for free.